how does a double check valve work

A butterfly check valve is also known as a dual folding disc double disc or splits check valve. It is commonly used on lawn irrigation systems fire sprinklers and mixed boilers.

What Is A Check Valve And How Does A Check Valve Work Empowering Pumps And Equipment

Check valves also known as nonreturn or one-way valves enable fluid to flow one way in a pipeline.

. It consists of two check valves assembled in series. They have two ports. Closing one valve lowers the pressure differential across the.

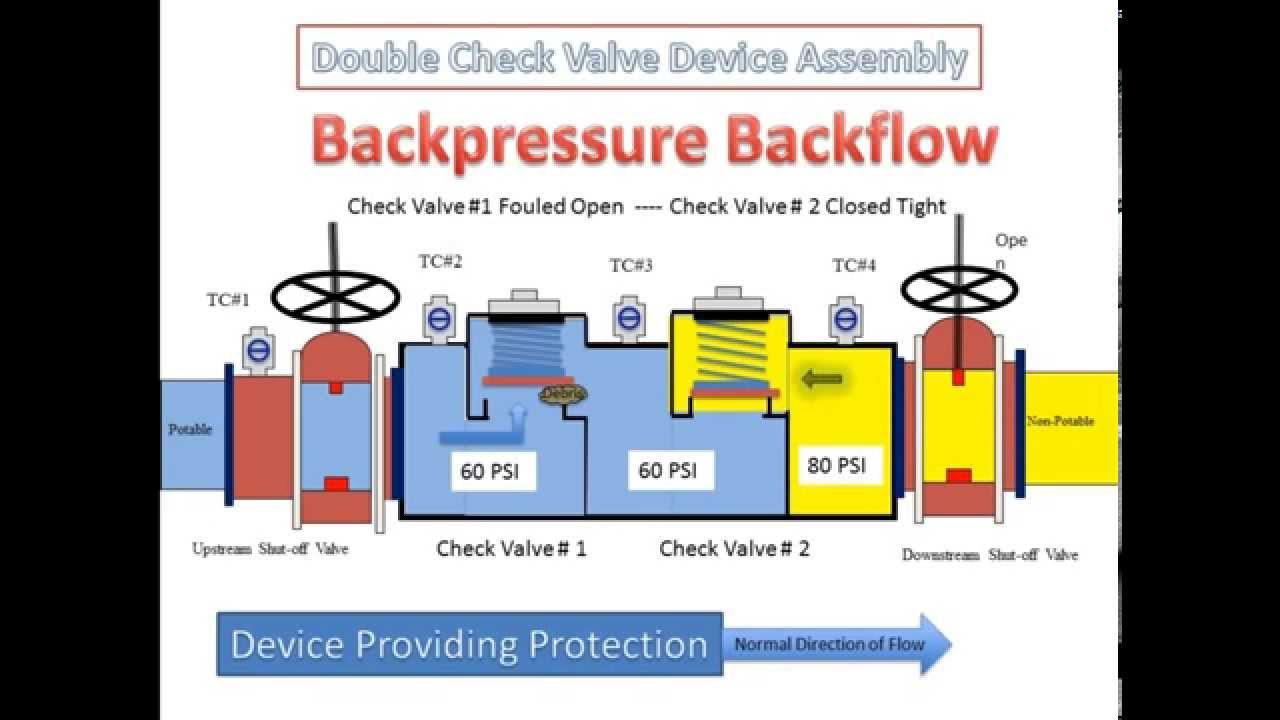

Double check detector assembly or DCDA means an assembly which consists of two independently operating check valves which are spring-loaded or weighted. This employs two operating principles. Posted by February 3 2022 late onset retinitis pigmentosa on how does a double check valve work.

How does a double check valve work. Because they only allow medium to flow in one direction theyre called one way valves or non return valves The basic function of a check valve is to prevent backflow in the system. The halves of the disc open toward the centerline as seen in the diagram during the forward flow of the fluid.

Ad Dual Disc Check Valves in Wafer Globe Lug Styles Iron Steel Stainless. The internal disc allows flow to pass forward which opens the valve. How does a check valve work.

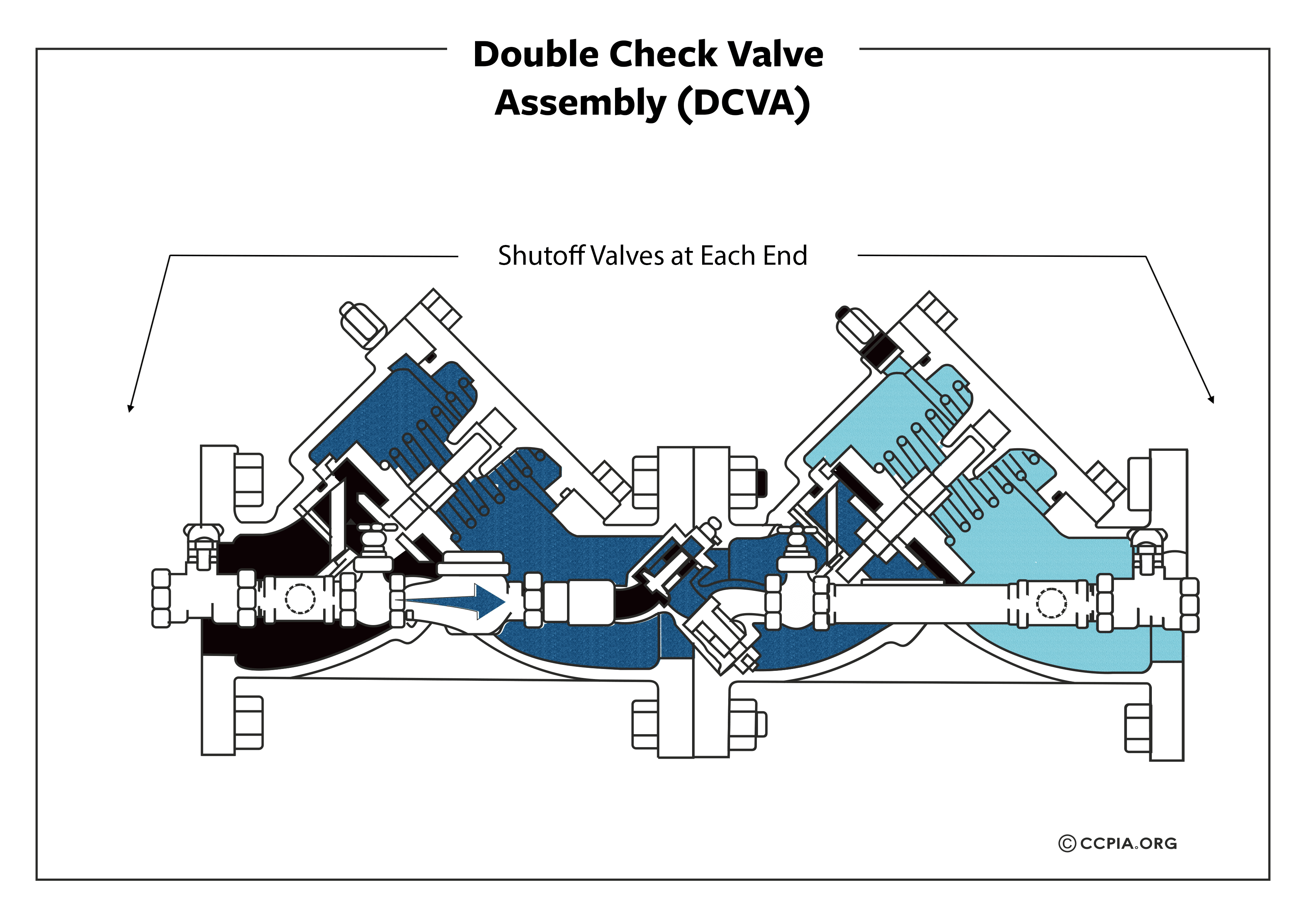

A double check valve or double check assembly DCA is a backflow preventer designed to protect water sources from contamination. Check valves are flow sensitive and rely on the line fluid to open and close. The double check valve is suitable for the prevention of back pressure and siphoning but is not suitable for high risk applications.

Double-check valves consist of two non-return valves connected in a series operating under two principles. Firstly one check valve will still act even if the other is. If one check valve jams wide open the other will still function.

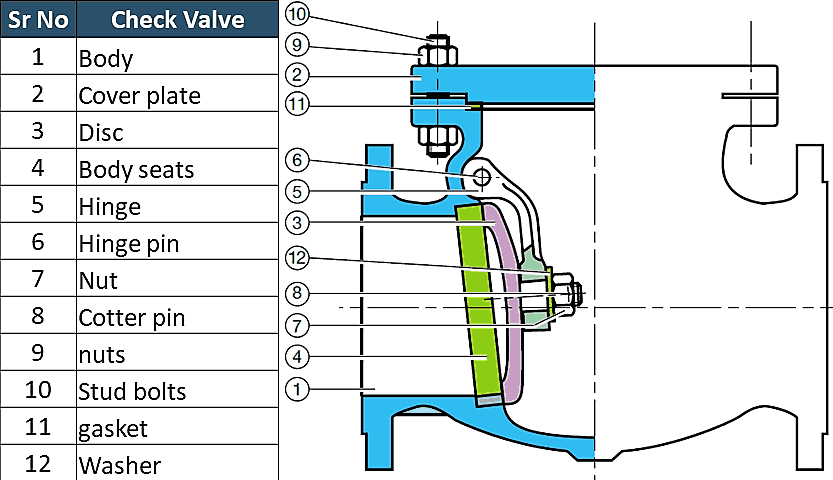

One for media input and the other for media output. This video illustrates how a Double Check Valve Backflow Prevention Assembly functions. A clapper hangs from a hinge clapper shaft or pin mounted to the underside of the bonnet.

It is different from the two-way check valves sometimes erroneously referred to as double check valves used in air brake systems on heavy trucks which select from the highest pressure source. This employs two operating principles. A double check valve or double check assembly DCA is a backflow prevention device designed to protect water supplies from contamination.

Because of their simple design check valves generally operate without automation or human interaction and instead rely on the flow velocity. With reverse flow the halves open and seal the pipe. It consists of two check valvesassembled in series.

Stayflow Selection and Service. A double check valve or double check assembly DCA is a backflow prevention device designed to protect water supplies from contamination. The assembly comes complete with a shut-off valve on each side of the checks as well as test cocks to test the checks for tightness.

This design inhibits backflow in a line. Functions of a Check Valve. A check valve is a type of valve that only enables medium to flow in one direction.

Check Valve Installation And Benefits Tlv A Steam Specialist Company Worldwide

Solutions For The Overlooked Forward Flow Test

What Is A Check Valve Learn About Check Valves Types And Parts

Check Valve Installation And Benefits Tlv A Steam Specialist Company Worldwide

Types Of Check Valves Different Check Valves Types Of Nrv Valves

Introduction To Check Valves The Process Piping

Backflow Preventers At Commercial Properties Ccpia

Comparison Between Swing And Dual Plate Check Valve Download Scientific Diagram

How Does A Backflow Preventer Work

Water Quality In Your Home Single And Double Check Valves Youtube

Hydraulic Pilot Operated Check Valves Hydraulic Repair Schematic

Check Valve Installation And Benefits Tlv A Steam Specialist Company Worldwide

How Do Check Valves Work Spec Sense Youtube

Backflow Preventer Vs Check Valve What S The Difference

Introduction To Check Valves The Process Piping

Non Return Valve Check Valve Lift Type Rehman Engineering Works